Knife Gate Valve Manufacturer.

"Plutontek" is a renowned and recognized manufacturer, exporter and supplier of Knife Gate Valves, from Pune, Maharashtra, India.

"Plutontek" is a renowned and recognized manufacturer, exporter and supplier of Knife Gate Valves, from Pune, Maharashtra, India.

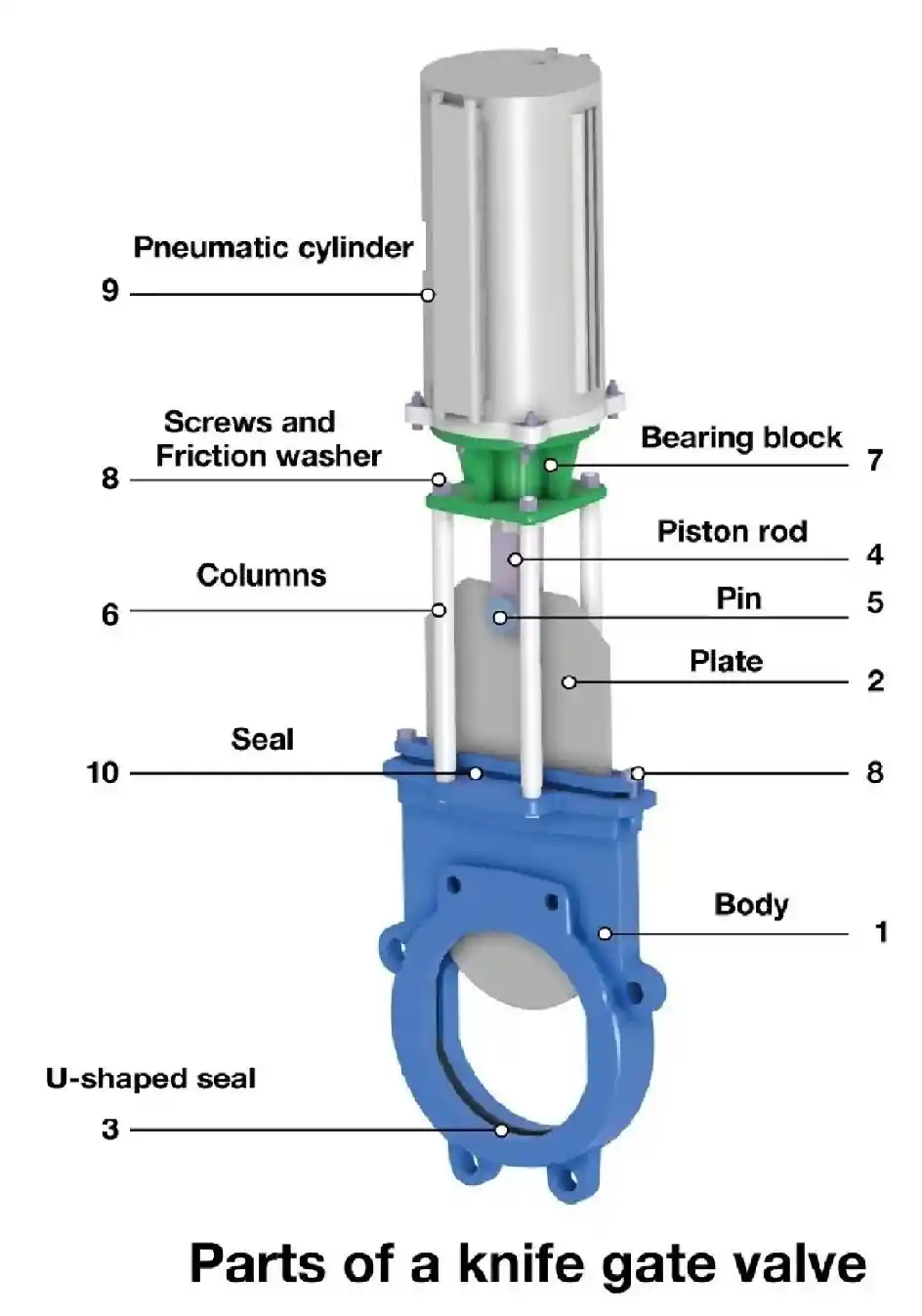

A knife gate valve is a shut-off valve or isolation valve, used to start or stop the flow in the piping. It is used in a variety of industries to control flow of liquids, solid-liquid mix or slurry. The gate of a knife gate valve is built with sharp edges to cut through high dense material flowing in the pipe. The valve uses a knife edge that can enter the flow stream and, if necessary, use the edge of the gate to separate any materials that might prevent the valve from sealing completely

For MildSlurry, liquid-solid mix, dry abrasive media

Pressure tight shut off for high concentration slurry

Pressure tight shut off for sea water, water and slurry

Pressure tight shut off for sea water, water and slurry

Knife gate valves are categorized by their design, which directly impacts their functionality and suitability for various applications.

Unidirectional Knife Gate Valves : Designed to allow flow in one direction and seal effectively against any reverse flow. These are ideal for applications with consistent flow direction, ensuring proper sealing and preventing any potential backflow.

Bidirectional Knife Gate Valves : These valves can seal against flow in both directions, providing reliable sealing in systems where the flow direction changes. This adaptability makes them well-suited for dynamic applications, offering enhanced performance in varying conditions.

50-300 mm

Upto 200 Deg C

5 - 10 Bar

Manual/Auto

SS/CI/WCB

Please do contact us for your query. We will provide you accurate solution

| Parameters | Supply Options |

|---|---|

| Design & Testing Standard | AWWA C520-14 / MSS SP-81 |

| Size Range | Unidirectional 50mm (2") to 600mm (24") Bidirectional 50mm (2") to 300mm (12") |

| Pressure Rating | PN3 (45 PSI), PN6 (90 PSI) and PN10 (150 PSI) depending upon housing material, primarily for liquid applications. |

| End Connection | With matching flanges / Wafer Type / Flangeless / |

| Temperature range | Up to 200 Deg C. |

| Material Of Construction - Body | Cast Iron, Cast Aluminium, Stainless Steel, Mild steel, Ductile Iron |

| Material Of Construction - Knife | SS304 / SS316 / As per application requirement |

| Knife / Gate surface treatment | Polished and lapped for greater seal with packing and seat |

| Material Of Construction - Stem | SS - Rising / Non Rising Type |

| Material Of Construction - Seat | Renewable metal to metal / Teflon / PTFE (Soft Seat) |

| Manual Operation | With Handwheel / Chain wheel |

| Automated Operation | With Electric Actuator / Hydraulic / Pneumatic Double Acting Cylinders |

| Optional accessories | Clevis foot bracket, Rod end aligner |

By operating the lifting plate (i.e. “Knife”) manually / by actuator (on/off), the path of flow literally cuts, creating complete closure against a soft sealing surface. Batten edge of the Gate (Knife-Edge) allows the tight shut off even when solid particles settles at the bottom of the Body. The soft sealing is rather used in low-pressure systems and hence is not designed to handle high pressures.

Knife Gate valves are used at relatively low pressure applications.

Knife Gate Valves (KGVs) started its journey in the Swedish Pulp and Paper industry in 1927. Since then, knife gate valves have traveled across the globe undergoing several alterations, however globally accepted the term “knife gate” as a generic name for each version of this valve.